Published on May 2, 2008 | Last Updated on September 13, 2025

It gives me pleasure to introduce a guest author to BIM ThinkSpace – Sohail Razvi. Through the wonders of web-based professional networking, I met Sohail and we started a discussion that continues to date. This is Sohail’s first web contribution into the topic and I’m delighted he’s chosen BIM ThinkSpace for his well-thought piece. The below article explores a new angle into BIM Framework generation as Sohail argues how it could develop around a set of well established, measurable and institutionalised framework, the CMMI.

BIM and the Process Improvement Movement

Building a case for a combined BIM-CMMI Framework

Introduction

The Architecture, Engineering, Construction and Facilities Management (AEC/FM) industry is almost certainly the only functionally-critical (and highly regulated) industry that builds its prototypes live on the production line. This is mostly still done without the benefits of digital modeling, prototyping and simulations as many peer industries have done (think of the car and aerospace industries for example). The consequences of working without such models are apparent, at times painfully, to anyone who has financed, built, owned, designed or operated a piece of built environment of any size or function.

Other major industries have quickly recognized the immense power of constructing and testing a virtual prototype of their product designs through digital techniques before ‘going live’. This ‘prototyping behavior’ has required an immense amount of effort by these industries to get their act together yet allowed their services and products to be repeatedly delivered to clients with dependable quality, timing and cost. In so many industries, the ability to manage and control an increasingly complex ‘product’ throughout its lifecycle is dependent on highly systemized processes and efficiencies acquired through digital technology.

Background

The unique character of the AEC/FM industry spans both the delivery of construction products as well as pre- and post-production services offered to its clientele/consumers. The resulting product – delivered through numerous channels – is a product that affects people, institutions, the environment, and is the sine qua non for many stakeholders’ bottom-lines.

In a recent commentary on their research covering these changes, authors Yoo, Boland and Lyytinen, (AECbytes Viewpoint #36 March 13, 2008) propose that:

“…digital technology (is) revolutionizing the AEC industry. Powerful 3-D visualization tools, combined with increasingly sophisticated digital modeling systems and centralized databases enable radically new ways of coordination among the many actors in an AEC project. Building Information Management (BIM) systems provide an integrated platform through which digitized construction and design information from diverse sources can be effectively communicated and coordinated. Digital tools to manage costs and schedules are being integrated into BIM systems, and supporting technologies like wireless networks, intelligent sensors, mobile computing and digital measurement systems are also being integrated with these systems to take full advantage of emerging digital infrastructures. The integrated use of digital technologies can significantly decrease cost and mitigate risks on complex projects, while enabling architects and builders to explore innovative building designs and new construction methods and materials.”5

It is understood that as the AEC/FM industry transforms itself into an intensely software centric paradigm, the ground rules (profoundly and unavoidably) have to get a make over as well. These transformations require vigilant and creative thinking and consideration:

- How the actors will come together and interact

- How the technology will affect the methodologies involved in the running and delivery of projects and

- Where and how the risks will be mitigated.

Considerable work in this area has been done in other industries and is currently being done within the AEC industry in Australia, Europe and the United States. These ground breaking efforts are being conducted by entities like the CRC-Construction Innovation, in Australia (check Sydney Opera Houses FM Exemplar), National Institute of Building Sciences in the USA (developers of the National BIM Standards), International Alliance for Interoperability (the developers of the IFC, IDM, etc), the American Institute of Architects (published Version 1 of the Integrated Project Delivery Guide in 2007) and many others.

In contemplating the immensity of this undertaking, to bring about fundamental changes to the industry, one of the early and essential tasks that needs to be undertaken – I would venture – is to study how other industries have handled these changes and, as a result, shifted their performance to a higher level of maturity, quality, production and delivery of products and services.

In this essay, I would however like to focus on a single area (and there are many others) of operations within the entire gamut of the AEC/FM operational disciplines: the business processes and methodologies that lead to high quality design and delivery of the construction product. It is in this context that I have considered the concepts of a ‘BIM Framework’ presented on this website in the series titled ‘BIM Episodes’ by Bilal Succar.

I would further argue that there exist many tested frameworks, that are being utilised to immense advantage by many other industries, that can also be developed and adapted to the AEC/FM industry. I would also venture in saying that there is good reason to study, define and perhaps modify the BIM Framework in the context of these tested frameworks. To further present this view, I have provided below a graphical illustration of just such a model that has been adopted by many well known organisations like Raytheon, IBM, Hitachi as well as relatively lesser-known software houses like 3H Technology and TrialStat Corporation in the USA to improve the quality of their operations, products and services delivered to clients.

The CMMI Framework – An Introduction 1, 2

The Capability Maturity Model (CMM) was developed by the Software Engineering Institute and the Carnegie Mellon University over many years. This started in 1986 as a response to the disconnect between engineering and business processes in the delivery of products or services. In its latest iteration, this framework has evolved into the ‘Capability Maturity Model® Integration’ – the CMMI®.

The CMMI is a process improvement model for the development of products and services. It consists of guidance for implementing practices that address development and maintenance activities covering the product lifecycle from inception, through design, to production, delivery and maintenance. It helps integrate and institutionalize these activities into the organizations’ collective knowledge so the processes can be (1) repeated with similar quality of results and (2) monitored for continued improvement. The application of CMMI has, with time, extended to industries outside the software development industry into banking, aerospace, car manufacturing, electronics to name a few. For this reason the SEI has continued to develop the applicability of its model to other industries. For example it’s currently extending the CMMI model to cover organizations delivering services rather than products 4. This will allow the model to cover activities required to establish, manage and deliver these services. In doing that the CMMI draws upon concepts and practices from other service-focused standards and models including Information Technology Infrastructure Library (ITIL), ISO/IEC 20000: Information Technology – Service Management, Control Objects for Information and related Technology (COBIT) and Information Technology Services CMM (ITSCMM).

Key to understanding the CMMI is the idea of process maturity. When a process is identified, understood, defined and measured, it ‘matures’. This means that it can be managed, revised, its defects eliminated and its effectiveness measured. Some of the benefits of implementing the CMMI framework in an organization or industry are:

- Creation of an explicit link between business objectives and design and engineering activities

- Expansion of scope and visibility of engineering activities and service activities throughout the lifecycle of the project to ensure they meet customer expectations

- Incorporation of additional areas of best practices where lessons learned from measurement methods, risk management and supplier management are included.

- Identification of organizational functions critical to successful products and services

- Better compliance with relevant ISO standards – where desired or applicable

The Premise

There are two fundamental ideas to be considered relating to the principles of process maturity.

First, does product quality benefit from using well-established configuration of processes and methodologies? In other words, is there even a need for such a framework in order to develop, build and maintain a product or service?

In the AEC/FM context, products can be tangible or intangible:

- Tangible products are those manufactured or built (example a facility or its components)

- Intangible products are those services that allow the product to be designed, constructed and maintained – similar to architectural design or facilities management services

It is now recognized3 through the experiences of many organizations that the implementations of tested Process Maturity models (similar to those promoted by the SEI) are highly beneficial:

- The quality of a system (AEC/FM product or a service) is highly influenced by the quality of the process used to acquire, develop, and maintain it.

- Process improvement increases product and service quality as organizations apply it to achieve their business objectives.

- Process improvement objectives are in fact aligned with business objectives

There are many process areas in the CMMI framework that can enhance the AEC/FM processes and activities, for example:

- Planning, Tracking and Schedule Management

- Requirements Definition and Configuration Control

- Quality Measurement and Continuous Improvement

- Process Assessment

- Evolutionary (continuous) Process Improvement

- Design Tracking and Management: this process area does not explicitly exist in the CMMI framework but is encapsulated in process areas called ‘Technical Solutions’ and ‘Product Integration’. Also, additional pieces are embedded in ‘Configuration Management’ and ‘Requirements Management’ process areas. Given the fundamental, cross-disciplinary and iterative nature of the design activity within the industry, a new process area dealing exclusively with Design Tracking and Management activities may be needed.

As you can gather, the emphasis is on ‘process improvement’ and the goal is to move from ill-defined and ad hoc, immature processes to demonstrably mature ones with improved quality and effectiveness.

Second, it stands to reason that we persistently need to monitor and measure results from implementing these processes in order to continuously improve them. Product and service performance improvement is not achievable without measurement and analysis. To achieve long-term business successes, it is essential to deploy an effective measurement and analysis program within organisations. This is required at several organizational levels and are partially addressed in the CMMI framework:

- Enterprise level – which affects the long term survival of the business (not covered by CMMI)

- Process level – the efficiency and effectiveness of organizations in accomplishing work

- Project level – realization of specific products or services for a specific customer or class of customers

- Product level – resolution of technical aspects of products or services necessary to meet customers’ requirements.

This highlights the question: can the above described CMMI approach be of benefit to the AEC/FM industry as it undergoes its current BIM-driven transformations?

It is clear that the world of facility design, construction and operations is increasing in complexity. This is brought about by multiple competing design/ownership factors including security, technology, sustainability, new materials as well as emerging space-usage concepts and configurations. The complexity is also increased as the end constructed product is necessarily the accumulation of factors and efforts by many disciplines and industries. In order for all these to work together, an overarching framework of best practices is essential to eliminate barriers and bottlenecks within the industry. The CMMI framework may well provide such an “opportunity to eliminate these through integrated models that transcend disciplines”. The focus can thus be holistic and focused on the design, construction and maintenance of the ‘product’ throughout its lifecycle.

The case for a BiCMM Framework?

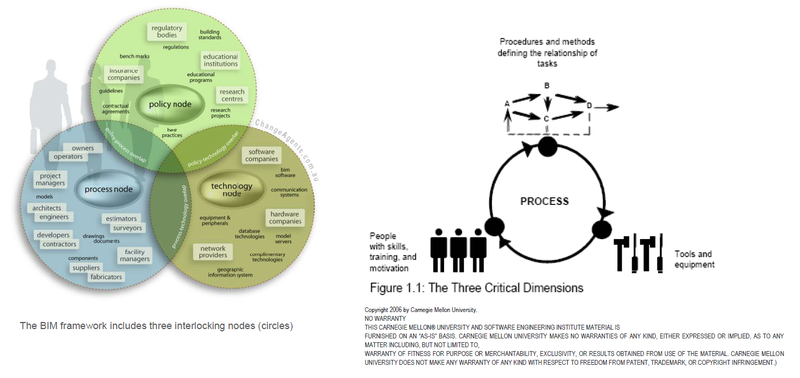

The discussions generated by the BIM Episodes are a step in the right direction. In Episode 7 of the series, the author introduced a ‘BIM Framework’ using a Venn Diagram of the three nodes: Policy, Process and Technology (reproduced below with the author’s permission). Contained within this illustration is an intriguing idea: what does the overlap in the Venn diagram represent? I would like to think that this overlie contains common characteristics between the three nodes and that it represents the ‘bonding agent’ holding it all together. I propose identifying this bonding agent as a ‘Building Information Capability Maturity Model’ (BiCMM).

The BiCMM framework of process improvement and maturity will ensure that Policies, Technologies and Business Practices used in the design, delivery and maintenance of Capital Facilities are organized in a manner that is not ‘stove-piped’ (as has been the tradition in our industry – where each discipline has had minimal cross-disciplinary interaction and collaboration, each working within their vertical stove-pipes). Given the iterative nature of the design activity, eliminating this behaviour will therefore create value for all stakeholders.

I will further propose that this framework can and should be developed around a set of well established, measurable and institutionalized practices available for study and analysis. A structure is required to organize the AEC/FM processes already in practice and new ones that need to be introduced as a result of BIM-driven transformations. It is essential that these practices be defined, controlled, monitored and improved upon on a continuous basis. This will have the potential of becoming an industry-wide standard framework which, when implemented in AEC/FM organisations, will measure their level of maturity and thus capability in delivering consistent results.

This organizational structure is available and can be adopted from the CMMI Framework. It is instructive to note that the BIM Framework’s ‘Three Nodes: Process, Policy and Technology’ (refer to Episode 8) are significantly similar to CMMI’s ‘Three Critical Dimensions’ of Process, People and Technology. Figure 1 below illustrates this point.

Figure 1

So what should be done to generate the ‘BiCMM’ Framework being proposed here and how can that be based on the proven process improvement principles like CMMI? I will suggest the following actions:

- First, there is a need to conduct a study to formally compile and document existing industry processes and methodologies. This will serve as a starting point and will generate a clearer direction to follow.

- Second, this should be followed by a ‘Gap Analysis’ study to (a) determine the need for improvement within existing processes and (b) identify required new processes. This will be followed by an attempt to cast these into a CMMI frame of reference.

- Third, this will then prompt the creation of new Process Areas on top of those currently existing within the CMMI framework to serve the exacting needs of the AEC/FM industry.

- And finally, guided by the CMMI experience, ‘Maturity Levels’ can be defined for these new and/or improved processes through well defined, measurable and monitored BIM Stages (refer to BIM Episodes – Episode 5) which will ultimately include all the three levels of technology, processes and policy.

Conclusion

There is much ‘business wisdom’ in working towards developing an industry specific framework to bring the AEC/FM in alignment with the constellation of industries that have already benefited from process improvement approaches. It is highly possible that, in the near future, industry clients may request services from AEC/FM players while demanding evidence of systemic operational efficiency. It is also possible that major clients (like governments and large facility owners/operators) will one day consider the adoption of frameworks – similar to CMMI and ITIL – a prerequisite for accepting proposals from designers, builders and other consultants. In fact, it is even possible to predict that such a day is fast approaching. In anticipation of that stipulation, we should start building the BiCMM framework with some urgency. Judging by benefits reaped by other industries, the rewards of adopting a process improvement framework may be too great to ignore or postpone.

References & Bibliography

- Chrissis, M. B., Konrad, M. & Shrum, S. (2007) CMMI Second Edition: Guidelines for Process Integration and Improvement.

- CMMI Product Team (2006) CMMI for Development V 1.2

- Gibson, D.L, Goldenson, D.R. & Kost, Keith (2006) Performance Results of CMMI-Based Process Improvement (https://www.sei.cmu.edu/cmmi/results.html)

- CMMI for Services Project website (Software Engineering Institute/Carnegie Mellon) (https://www.sei.cmu.edu/cmmi/models/CMMI-Services-status.html)

- Yoo Y, Boland R.J. & Lyytinen, K. (2008) Digital Transformation of the AEC Industry: An Innovation Perspective (AECbytes Viewpoint #36 March 13, 2008)

- NIST (2004) Cost Analysis of Inadequate Interoperability in the U.S. Capital Facilities Industry. IN Gallaher, M. P. O. C., A. C.; Dettbarn, J. L., Jr.; Gilday, L. T. (Ed.), National Institute of Standards and Technology.

- NIBS – Facility Information Council (2007) The National BIM Standard Version 1 – Overview, Principles and Methodologies

- AIA-California Chapter (2007) Integrated Project Delivery: A Guide (Version 1)

- McCuen, T & Suermann, P (2007) The Interactive Capability Maturity Model and 2007 AIA TAP BIM Award Winners (AECbytes Viewpoint #33 December 6, 2007).

Acknowledgements

Dr. Ruth Buys, VP Process & Quality Management, QinetiQ-NA, has helped me with suggestions for improving the content and with proof reading of this paper.

Aliya Razvi, B.Sc. Doctoral Student, Clinical Psychology and Program Administrator, University Scholars Program, George Mason University, Fairfax, Virginia, USA. Aliya read and offered suggestions to improve readability and formatting.

Bilal Succar, Integrated Practice Consultant, ChangeAgents AEC, BIM Researcher, RMIT University, PhD Candidate, CIB, RAIA (Assoc) and IAI-AC. Bilal has read and offered suggestions and changes for content and readability.

Cite as: BIMe Initiative (2025), 'BIM and the Process Improvement Movement', https://bimexcellence.org/thinkspace/bim-and-the-pro/. First published 2 May 2008. Viewed 31 December 2025